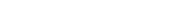

This month we talk to Duncan Price who discusses Cave Diving, Thai cave rescue, and more... as a Cave Explorer, Chemical Engineer, Author and all round interesting person - this is a must read!....

Let's talk about your expertise. What interests you and drives you to master fluid applications?

"I’m a cave diver in my spare time. I’ve been involved with caving and diving for nearly 30 years though caving is my primary hobby. The diving aspect is purely a means to explore caves both in the UK and overseas, just like having a car is essential to get to places not served by public transport."

What piqued your personal interest in this field?

"In 2000 my friends and I became interested in making longer and deeper cave dives. The means to do this was to use a rebreather – a device which removes carbon dioxide from your exhaled breath and recycles it. It is much more efficient than simply breathing air from a cylinder and blowing out bubbles. It’s old technology and the Cave Diving Group to which I belong has been using them on and off since 1946 when it was formed. It is the longest-lived diving organisation in the world."

Tell me how you ensured the safety of the rebreather...

"Of course you can’t simply scrub out CO2 from your exhaled breath and inhale it again as you’d simply run out of oxygen. A closed-circuit rebreather must add a trickle of oxygen to make up that used up by the diver’s metabolism. We needed a means to do this and turned to Swagelok needle valves to meter a feed of pure oxygen into the device. There are commercially available rebreathers which are available to sports divers these days, but they are bulky units designed for use in the sea not the confines of an underwater cave. We built rebreathers that could fit on your chest or wear on your side so that you could squeeze through small gaps or even take them off and push them ahead of you. It’s the sort of stuff that gives most people nightmares!"

Where have your rebreathers been used?…

"An early success was using a slimline rebreather to establish a new UK cave diving depth record at Wookey Hole Caves in Somerset of 90 metres. I’ve taken my “toys” to France and the USA and helped others build similar devices for underwater cave exploration."

What are you currently working on?

"There are always opportunities for improvements in our gear. The cave environment is quite harsh and making more rugged devices is a challenge. One design criterion is that you can kick your breathing apparatus around a car park and then take it diving."

Where/when was your last field trip/site visit?

"I’ve used my rebreathers to enable me to stay underwater for longer and map caves using hand-held SONAR wands and waterproof laser range finders. Over several dives lasting up to 2 hours I mapped nearly a kilometre of submerged cave passage taking measurements every 5 metres - it’s both cutting edge and laborious."

Tell me more about your involvement in the Thai cave rescue...

"As well as flow control valves we also employ quick-disconnects to be able to change gas supplies over, underwater. The rescue of a group of boys trapped in a Thai cave in 2018 used quick-disconnects to be able to swap cylinders over without interrupting their breathing supply and keep the casualties alive."

Do you prefer focusing on small sections of a fluid system or is a whole overview generally more productive?

"I generally try to keep the component count as low as possible – the cheapest and most reliable component is the one you don’t have…"

What are your favourite Swagelok products and why?

"Braided steel hoses feature in many of my designs – they take a lot of abuse. I use both standard female disconnects and the low profile instrumentation type so that I can feel which one is which with gloves on. It is critical not to connect the wrong gas mixture and although I like to colour code things, a tactile indication helps."

What are the 3 most essential systems or tools you use to complete your project?

"It might seem odd, but I like to browse a hard copy product manual for ideas. As I alluded to earlier a 'Keep It Simple Stupid' approach works best. As I’m doing all of this out of my own pocket I give very careful thought to every order."

What are the benefits of using Swagelok in your opinion?

"It is the brand leader. I’ve had a personal account with Swagelok since 2002 and I’ve been quite loyal although I’m not averse to using other suppliers if I can’t find the right fitting – I have got friends to buy components in the US or even Australia and ship them to me."

How does Swagelok Bristol support your design/fabrication?

"I often order by telephone and the staff are very patient and helpful when I don’t quite have the right part numbers. They are happy to give advice on what I need to achieve what I want to do."

How do customers start conversations with you?

"Perhaps because of my encyclopaedic knowledge of the Swagelok range for such a niche application my friends often message me on social media for advice."

Thanks so much Duncan!

Use the links below for more insight into Duncan's expertise, cave diving experience and publications... http://www.sump4.com/about.html

.png)