Fixed volume sampling applies mainly to liquid sampling, where a specified volume of liquid is transferred to the sample container during the sampling procedure.

Think before you sample: The dangers of full-pressure sampling

Everything you need to know about blanket ordering

Blanket ordering is an agreement between Swagelok Central UK and you (our customer) to deliver our products and our custom fabrications - small and larger builds. This article lets you know what we can offer to support your individual requirements.

Topics: Service Support, risk mitigation, blanket ordering

We talk to Duncan Price, Cave Diver & Chemical Engineer

This month we talk to Duncan Price who discusses Cave Diving, Thai cave rescue, and more... as a Cave Explorer, Chemical Engineer, Author and all round interesting person - this is a must read!....

Let's talk about your expertise. What interests you and drives you to master fluid applications?

"I’m a cave diver in my spare time. I’ve been involved with caving and diving for nearly 30 years though caving is my primary hobby. The diving aspect is purely a means to explore caves both in the UK and overseas, just like having a car is essential to get to places not served by public transport."

What piqued your personal interest in this field?

"In 2000 my friends and I became interested in making longer and deeper cave dives. The means to do this was to use a rebreather – a device which removes carbon dioxide from your exhaled breath and recycles it. It is much more efficient than simply breathing air from a cylinder and blowing out bubbles. It’s old technology and the Cave Diving Group to which I belong has been using them on and off since 1946 when it was formed. It is the longest-lived diving organisation in the world."

Tell me how you ensured the safety of the rebreather...

"Of course you can’t simply scrub out CO2 from your exhaled breath and inhale it again as you’d simply run out of oxygen. A closed-circuit rebreather must add a trickle of oxygen to make up that used up by the diver’s metabolism. We needed a means to do this and turned to Swagelok needle valves to meter a feed of pure oxygen into the device. There are commercially available rebreathers which are available to sports divers these days, but they are bulky units designed for use in the sea not the confines of an underwater cave. We built rebreathers that could fit on your chest or wear on your side so that you could squeeze through small gaps or even take them off and push them ahead of you. It’s the sort of stuff that gives most people nightmares!"

Where have your rebreathers been used?…

"An early success was using a slimline rebreather to establish a new UK cave diving depth record at Wookey Hole Caves in Somerset of 90 metres. I’ve taken my “toys” to France and the USA and helped others build similar devices for underwater cave exploration."

What are you currently working on?

"There are always opportunities for improvements in our gear. The cave environment is quite harsh and making more rugged devices is a challenge. One design criterion is that you can kick your breathing apparatus around a car park and then take it diving."

Where/when was your last field trip/site visit?

"I’ve used my rebreathers to enable me to stay underwater for longer and map caves using hand-held SONAR wands and waterproof laser range finders. Over several dives lasting up to 2 hours I mapped nearly a kilometre of submerged cave passage taking measurements every 5 metres - it’s both cutting edge and laborious."

Tell me more about your involvement in the Thai cave rescue...

"As well as flow control valves we also employ quick-disconnects to be able to change gas supplies over, underwater. The rescue of a group of boys trapped in a Thai cave in 2018 used quick-disconnects to be able to swap cylinders over without interrupting their breathing supply and keep the casualties alive."

Do you prefer focusing on small sections of a fluid system or is a whole overview generally more productive?

"I generally try to keep the component count as low as possible – the cheapest and most reliable component is the one you don’t have…"

What are your favourite Swagelok products and why?

"Braided steel hoses feature in many of my designs – they take a lot of abuse. I use both standard female disconnects and the low profile instrumentation type so that I can feel which one is which with gloves on. It is critical not to connect the wrong gas mixture and although I like to colour code things, a tactile indication helps."

What are the 3 most essential systems or tools you use to complete your project?

"It might seem odd, but I like to browse a hard copy product manual for ideas. As I alluded to earlier a 'Keep It Simple Stupid' approach works best. As I’m doing all of this out of my own pocket I give very careful thought to every order."

What are the benefits of using Swagelok in your opinion?

"It is the brand leader. I’ve had a personal account with Swagelok since 2002 and I’ve been quite loyal although I’m not averse to using other suppliers if I can’t find the right fitting – I have got friends to buy components in the US or even Australia and ship them to me."

How does Swagelok Bristol support your design/fabrication?

"I often order by telephone and the staff are very patient and helpful when I don’t quite have the right part numbers. They are happy to give advice on what I need to achieve what I want to do."

How do customers start conversations with you?

"Perhaps because of my encyclopaedic knowledge of the Swagelok range for such a niche application my friends often message me on social media for advice."

Thanks so much Duncan!

Use the links below for more insight into Duncan's expertise, cave diving experience and publications... http://www.sump4.com/about.html

Topics: Service Support, Interview Series

Calling all submariners! Building periscopes at Broadmead, Plymouth

We have taken an initiative at Swagelok Central UK this year to support the STEM education of Primary School children in the Southwest of England.

Topics: Engineering, Brain Drain, Charity

This interview series is with Richard Walsh, Engineering and Maintenance Manager at A-Gas. From a Chemical background Richard talks about the culture in the refrigeration industry and the necessity for reliable global supply.

Lets talk about your industries, who do you serve?

A-Gas has over 25 years’ experience in the supply and life-cycle management of refrigerants and associated products. We are a leading supplier to the Heating, Ventilation, Air Conditioning and Refrigeration industries, and our product portfolio extends to serve the automotive and fire protection industry.

Personally, I have been working at A-Gas for the last 13 months now and these are new sectors for me to work within. It has been a great opportunity where I have been able to demonstrate I can learn a new industry and bring my previous experiences with me to help move the business forward. A-Gas is in a great sphere at present within the Refrigeration industry changing as a result of the F-Gas regulation.

What piqued your personal interest in this field?

I have previously worked within the Chemical Industry from a Product Delivery perspective, supporting all the Oil Majors across the Globe. A-Gas has given me the opportunity to delve into the Processing side of the Chemical Industries and understand the intricacies involved to ensure customer demand is met on a daily basis. A-Gas has a fantastic culture where people are empowered and encouraged to better themselves and contribute to the success of our business. I feel privileged to be able to work with a team that are forward thinking, focused on improving site performance, and aspired to grow our operations.

What are and how did you end up solving your customers problems?

When our customers grow, A-Gas must grow. We must continue to meet demand in an ever-changing industry. We must ensure our customers have the right products, in the right quantity and in the right place. We must ensure we can continue with Business As Usual every day of every week.

Early last year it was becoming evident that we were outgrowing our existing site. We were stocking more products, expanding our cylinder fleet, improving our in house capabilities and growing our team. We made the decision to source a bigger facility to house our distribution activities and better meet the needs of our customers.

Bringing our new facility on site was a challenge for the entire A-Gas team. The whole organisation pulled together to ensure the facility was ready to operate as a logistics base, with infrastructure programmes implemented, operational processes relocated and the upheaval of moving the staff to make it all happen.

The project involved many talented individuals to pull off the move and deliver an excellent facility that will position A-Gas well moving forward.

Critical vendors and components such as those manufactured and supplied by Swagelok have helped to support us, giving us piece of mind that the equipment supplied for such a project is the best available and fit for the applications we need them for.

Tell me about the location of some of your installations…

The equipment that Swagelok components go into are based all over the world, from South Africa, Australia, USA, to here in our European Territory within the Netherlands, Germany and the UK. The A-Gas group continues to look at its strategic growth and ensure its facilities are fully utilised, whilst sharing best practice and learning from each other. The ability to adapt and deliver the services and products where the customer needs them is key to our success. The business and installations around the world work and evolve to ensure that we provide the best service that we can. The global business needs to have confidence in the equipment it is using, to know that it will work first time, every time. We also need to have confidence in the after sales support provided by our suppliers so that if we do have any issues that these can be resolved quickly. Having dependable, reliable, global suppliers are critical to this goal.

Where/when was your last field trip/site visit?

Today. Based in Portbury, near Bristol, our fantastic site is my office. I have the fortunate position where everyday I get to work with a team of people who are key to the success of A-Gas. We ensure that the equipment our production team depend upon works efficiently and effectively to deliver the product required by the customers on time and in the right place.

What are you currently working on?

Currently we are working on upgrading parts of our UK facilities to improve capacity, and efficiency, whilst implementing the best available solutions for our processing plants across Europe. This ranges from upgrades to our industrial gas facilities, improvements to our reclamation capability and implementing state of the art business system solutions.

Tell me a success story...

Obtaining a new site, stripping out the old infrastructure and installing a custom-built facility to meet the needs of our ever-expanding business is one of our great success stories. Improving operational efficiencies, implementing lean processing principles and ensuring our normal operations continued Business As Usual with no disruption to our customers was of paramount importance. And I am pleased to stand here today and say we did it.

The A-Gas ‘Together We Can’ spirit is inspiring to see every day. Individuals from all backgrounds and levels of experiences come together to resolve the issues we face, whether project related or part of our day to day tasks, and look to implement solutions to stop it happening again. We really are one team.

Do you prefer focusing on small sections of a fluid system or is a whole overview generally more productive in terms of ROI?

Whole overview is critical. In this type of industry a small change or deviation could have a profound impact on another part of the process. This can range from reduced up time of equipment with early equipment failures, operational processes being impacted with inefficiency in throughput, to the inability to meet the needs of our customers. An eye for detail is crucial to success, but if this is taken out of context or implemented without consideration of the overall system it could have catastrophic results. Therefore always referring back to the bigger picture and understanding the wider implications a small change, improvement can has is key to the success of the UK operations.

What are your favorite Swagelok products and why?

An integral part of the A-Gas facilities are the valves, fittings and tubing which form parts of the process equipment. These items are critical to our ability to be able to meet the demands of our customers as any downtime will have a significant impact on supply. Therefore having a reliable supplier like Swagelok who can meet our requirements for new equipment, spares and replacement parts is a very valuable differentiator for A-Gas. The Swagelok components supplied are of a high standard and very reliable in the applications we use them within. The equipment is also easy to service allowing the maintenance team at A-Gas to keep on top of their schedules for these items and focus on other critical aspects of the plant.

What are the benefits of using Swagelok in your opinion?

With continued availability, excellent quality, ease of installation and great support services, A-Gas have been using the Swagelok product offering for over 20 years and it continues to form part of our engineering solutions today.

How does Swagelok Central UK support your design/fabrication?

We see Swagelok as an extension of our capabilities to help deliver the required solutions we need to meet our everyday customer demands. The Swagelok Central UK team continuously offer support to find solutions, whilst providing training for our team and sharing their ever growing knowledge base with us.

How do customers start conversations with you?

We love talking to our customers and prospects whether via phone, email or face to face. Social media is playing a big part in our daily communications with people contacting us via linked in, Instagram and Facebook. Why not take a look at our website for more information on A-Gas: We do a lot more than you think!

Topics: Service Support, Interview Series

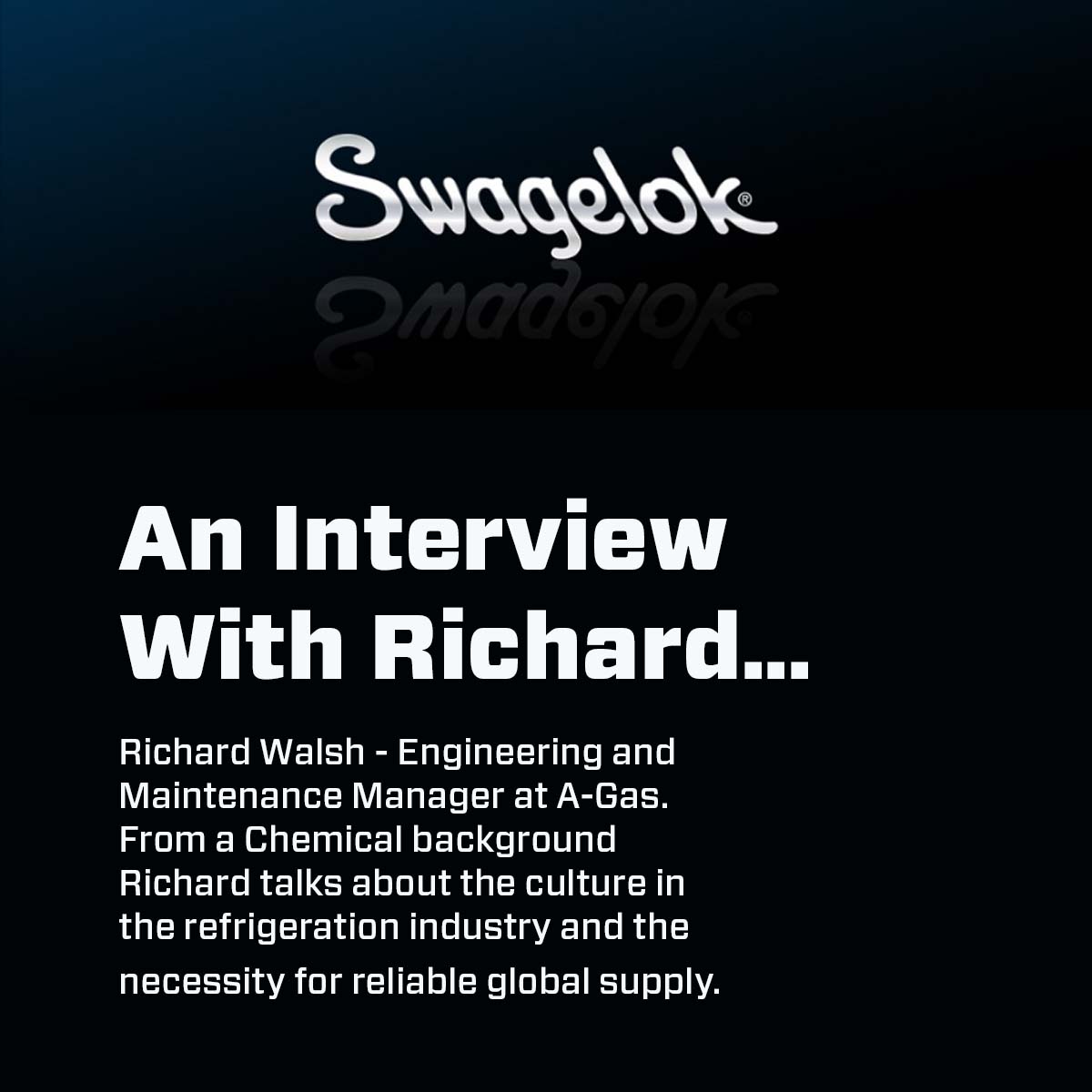

Are you swaging hundreds if not thousands of tube fittings?

We can assemble Swagelok product in high volume. We supply you ready swaged connected and tested fittings, tube and systems. Saving you valuable time and workshop space.

Topics: expertise loss, Service Support, Custom, Grab Sampling, fabrication

Topics: fabrication, welding, orbitalweld

We fabricate Swagelok components for our customers. This can range from providing simple tube bends to building turnkey panels designed to control complex gas mixtures and flows that are then installed by the customer.

Topics: Custom, Grab Sampling, fabrication, welding

What a day! The weather was beautiful, the sun cream was being passed around, the iced drinks flowing and Tony Copley was sweltering over the BBQ.

Topics: Portishead Soap Box

This interview series is with John Foster, Managing Director at Sarum Hydraulics LTD. A true engineer at heart, John designs, engineers and manages a company that has a passion for innovative and high quality products.

Let’s talk about your industries, who do you serve?

Sarum Hydraulics have built a very wide customer base over 37 years. Units have found their way into every industry where people are looking to use a hand pump to pressure test, dispense, charge, actuate, calibrate, jack or work hold. Often these are one off units and people only come back after fifteen years when they need a seal kit. Volume users of our kit are the medical, aerospace, defence, fire, offshore, process industry as well as the more generic “hydraulics” industry.

What piqued your personal interest in this field?

It’s a familiar story for good products that have established a place in the market. In this case it is a family business with three clever designers involved. Ron, John and Tony Foster as a father and two sons must have pumps in their DNA. The Micropac pump came from a sales enquiry on an exhibition stand. A big plc couldn’t find a decent hand pump that would operate an innovative trench shoring system using water - that was 37 years ago. People still need a decent high-pressure hand pump that will cope with multiple fluids, offer very low corrosion and an extended service life. Professionals still value those features today. I reckon it is still a unique product in the world.

How did you end up solving your customers problems?

Wind turbines have been big for Sarum Hydraulics. And so has our range of compact and inexpensive cartridge hand pumps that are installed into a C10-2 cavity in a manifold. We solved wind turbine manual hydraulics problems by offering the right level of corrosion resistance where it was needed, normally replacing legacy units that kept on failing. Whether it is was hostile environments in the North Sea, India, the Gobi Desert or any number of other locations, we have been able to offer precise solutions from stock parts. Fitting hard chromed 316 stainless piston rods to entry level models to fight corrosion or over-engineering a handle mechanism to battle misuse have been important to our customers.

Tell me about the location of some of your installations…

Micropac pumps have always had the travel bug! Diving bells and sub-sea actuators are one extreme. Ground support equipment to test jet engines or dispense Eastman Chemical “skydrol” are flown around the world. Valve actuators in extremely cold regions truly test our low temperature know-how. There are few hospitals in the UK that don’t have our equipment in them. Wind turbines in the Gobi Desert use our innovative cartridge pumps. Swagelok travels the world with Micropac and a Chinese firm buying our kit for their domestic wind turbines in the last few years has been a big achievement for a specialist British manufacturer.

What are you currently working on?

I am working on a few new units that will go into our catalogue and will find international demand through the internet. Our 316 stainless steel equipment is high quality, very cost effective and has a solid following. We are slowly adding complementary products to the 316 range. Making life easy for international customers, even at the design stage, is big for me. The days of purely thinking of the British market are long gone.

Tell me your product of the moment?

Our new MD series two speed 316 stainless two speed pump is our star. Having made big numbers of a chunky anodised alloy two speeder that sold against various legacy models for testing and jacking, I agonised about how to cut the space envelope right down and make it in 316 stainless for true corrosion resistance. I did it with our Micropac MD two speed pump, and we have people from all over the world buying them. It’s great!

What do you especially like in the Swagelok product range and why?

We go back to day one with Swagelok. Our call when we designed our Micropac pump back in 1982 was that you needed to make a well-engineered, quality product that was easy for Offshore and Aerospace to specify. And what a great fit the Swagelok range has been with our kit. Whether it has been fittings, valves or couplings, Swagelok has been the first port of call over all those years. It is nicely made as well, which unsurprisingly still counts for Engineers.

Which Swagelok products have worked particularly well for your business?

The double ferrule fittings are a joy to use for our fitters and are the first choice on any pipework. I still love working with them. Over the years we have used lots of small pipe end check valves and relief valves. The C series check valves and adjustable cracking pressure CP or CPA are amazingly useful in the right application. I still rate the integral bonnet needle valves like the SS-1RS4. They have a lovely feel compared with the competition! And finally, we use loads of Swagelok 316 hollow hexagon blanking plugs SS-HPST. We’re fans. I use them wherever I can on new designs.

Tell me a success story…

Even niche products mount up over 37 years. Somebody came to us with an aerospace test unit that was used throughout the world. The legacy design was massively complicated, including some truly exotic US parts, we simplified our design, using a modular Micropac hand pump incorporating all the control valves for the fluid system running on jet fuel. The original unit used a chunky four way valve and our masterstroke that really made this product was to integrate a Swagelok multi-way instrumentation ball valve SS-43Y into our unit. It fits the job perfectly. It has been a great success story for our company.

Do you prefer focusing on small sections of a fluid system or is a whole overview generally more productive in terms of ROI?

That is an interesting question for a firm who sell roughly equal values of a specialist pump component that somebody else will integrate into their fluid system and also Micropac pumps as finished test units ready for use. What wouldn’t work on an operational level for us is manufacturing whole fluid systems from bought in parts. In the internet age, I think we have become more interested in growing the business through adding new catalogue pump products with a global market. There is still a place for one off fluid systems achieved by customising our Micropac pumps and adding components like Swagelok parts to meet a customer requirement. Lots of “one-offs” are actually sold throughout the world. Micropac pumps have always been modular and able to be customised very cost effectively.

Want a Micropac hand pump fitted with a neat Swagelok 4CPA low pressure relief valve? No problem.

Terminate a delivery hose in an industry-standard Swagelok SS-QC8 female quick coupler? Easy!

We can add value using proven quality parts that are known anywhere in the world.

How many projects are you working on at any time?

Ask any designer and they will be thoughtful! There are always the big commercial products of the day, products that bubble on and hopefully will come good at the end of a long process in contrast there are those products that never quite happened for some reason but will feed into something else that fires up.

What are the 3 most essential systems or tools you use to complete your project?

3D modelling meets old fashioned drawing at Sarum.

Innovative products need good ideas at the design stage. A mix of tried and tested plus a new way of doing something or a new material.

Let me illustrate the design process at Sarum Hydraulics.... ideas take shape on Fabriano paper using lovely Pentel pencils or flow into Solidworks and Autocad. Information and specifications of 3rd party items are researched through supplier websites and catalogues. Our vintage Swagelok catalogue is still there alongside the web site. Finally, 37 years of experience helps us develop a product through to launching it in our catalogue and calling it “Micropac.”

For us the three design essentials are;

- Ideas

- Supplier Information

- Lengthy Experience

What are the benefits of using Swagelok in your opinion?

Nicely engineered quality products make a great first impression. They are a pleasure to install and use.

How do customers start conversations with you?

We still love talking to people. It is always exciting to chat to designers, specifiers or even the end user. They telephone us or send an e-mail. Now they are even asking questions through Twitter or our Sarum Hydraulics YouTube channel. If a customer can’t find exactly what they want from a catalogue or have a specific problem, there will be some reason why they will contact us. Specialising in a niche range of hydraulic and fluid system products has allowed us to offer some really innovative solutions to our customers. Maybe a conversation ends up with one of our massive range of Micropac hand pumps. Maybe the need is for a custom manifold integrated with standard parts will provide a very cost effective hand pump that a customer will “own brand” and sell with their actuators, day surgery trolleys, fire misting systems or a myriad of other applications. Or we are able to add fluid system components to one of our pumps to meet that special need.

Thank you John!

Topics: Service Support, Interview Series

.png)